Discover ETAC’s design considerations for custom dry-type transformers, including core materials, winding configurations, and safety standards.

August 7th, 2024

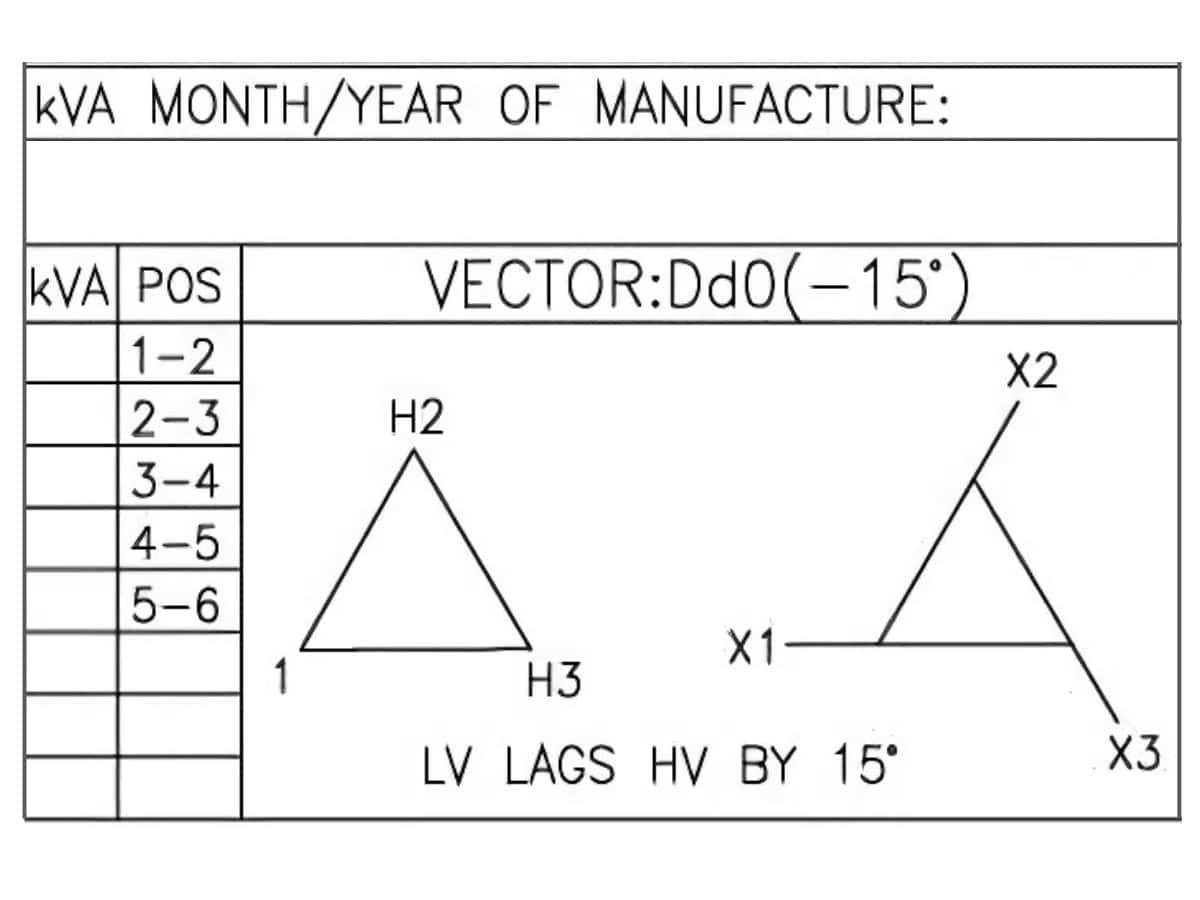

In the last article, we covered core material selection, winding configurations, and winding materials. In this article, we will delve into additional critical design aspects of ETAC’s custom dry-type transformers, including insulation systems, cooling methods, enclosure types, and the importance of adhering to safety standards like CSA C9.

The insulation system is crucial for the safety and longevity of dry-type transformers. ETAC offers various insulation materials to ensure reliable performance:

Selecting the appropriate insulation system ensures the transformer’s reliability and safety under various operating conditions.

Effective cooling is essential for maintaining the performance and longevity of dry-type transformers. ETAC employs different cooling methods based on the application requirements:

The choice of cooling method depends on the transformer’s power rating, operating environment, and cooling efficiency requirements.

The enclosure of a dry-type transformer is crucial for protecting it from environmental factors and ensuring safety. ETAC provides enclosures that meet different standards to suit various applications:

Choosing the right enclosure ensures the transformer is adequately protected and performs reliably under specific environmental conditions.

Compliance with safety standards is essential to ensure the reliable and safe operation of dry-type transformers. At ETAC, we adhere to the CSA C9 standard for our custom dry-type transformers.

Compliance with safety standards is essential to ensure the reliable and safe operation of dry-type transformers. At ETAC, we adhere to the CSA C9 standard for our custom dry-type transformers.

The CSA C9 standard, developed by the Canadian Standards Association (CSA), provides guidelines and requirements for the design, construction, testing, and performance of dry-type transformers. The standard ensures that transformers meet the necessary safety and reliability criteria, making them suitable for use in a wide range of applications.

Key Aspects of CSA C9:

Adhering to the CSA C9 standard ensures that dry-type transformers are designed and manufactured to meet high safety and performance standards, providing reliability and peace of mind to users.

ETAC provide fully customized dry type transformer, features include but not limited to:

Designing custom dry-type transformers at ETAC Service & Supply involves careful consideration of various factors to ensure optimal performance, reliability, and safety. Key considerations include core material selection, winding configurations, winding materials, insulation systems, cooling methods, enclosure types, and adherence to safety standards such as CSA C9. By addressing these aspects, ETAC engineers develop transformers that meet specific requirements and deliver efficient and reliable performance in diverse applications.