January, 2026

Stainless Steel Substation Transformers in harsh environments are designed to operate reliably where corrosion represents a significant risk. Unlike transformers with painted carbon steel tanks, these units use 316 grade stainless steel in their construction, providing superior resistance to moisture, salinity, and aggressive chemical agents.

For this reason, this article explains why this type of design serves as a key solution for substations located in coastal areas, industrial sites, or regions with high environmental exposure, where conventional equipment tends to deteriorate prematurely.

A substation transformer is an electrical device used to step voltage levels up or down within the power grid, enabling the safe and efficient transfer of electrical energy between generation, transmission, and distribution systems. Its reliability is critical, as any failure can directly impact power supply continuity.

316 grade stainless steel is known for its high resistance to corrosion, even in environments with chlorides, marine exposure, or industrial contaminants. In a substation transformer, this material is primarily used for the tank and external structural components, which are continuously exposed to environmental conditions.

As a result, the use of stainless steel eliminates reliance on protective coatings that can degrade, peel, or require frequent maintenance over time.

316 stainless steel construction allows the transformer to maintain structural integrity over extended periods, even in conditions where severe oxidation quickly affects traditional equipment.

By reducing deterioration of the tank and external components, the design significantly extends the transformer’s service life, minimizing the need for premature replacement.

The inherent durability of stainless steel reduces inspections, repainting, and corrosion-related repairs, resulting in lower lifecycle operating costs.

In many projects, stainless steel transformers are installed as direct replacements for existing units that have experienced severe corrosion after years of operation in aggressive environments.

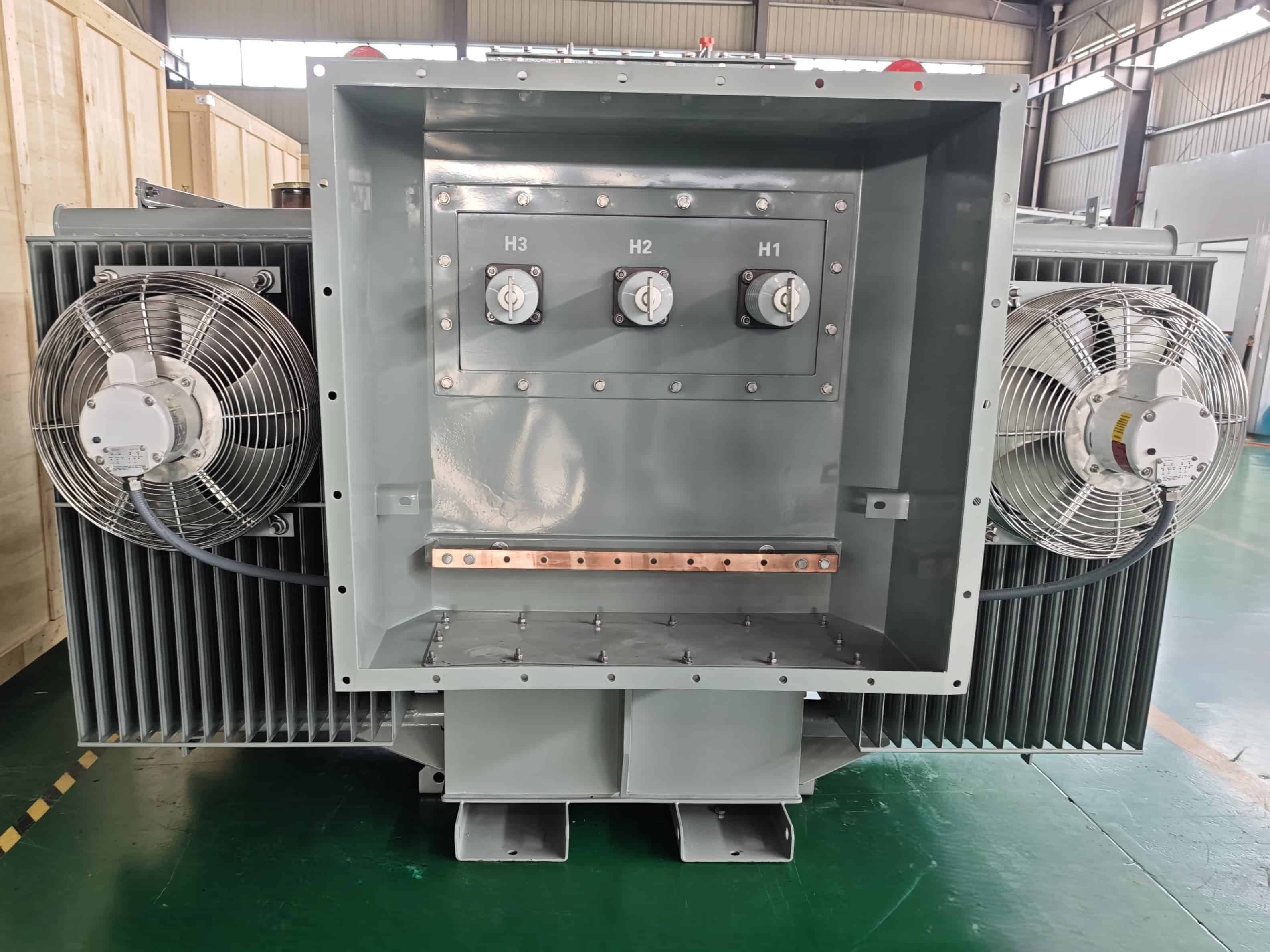

ETAC designs and manufactures these transformers in accordance with CSA Standard C88.16 and our standard design incorporates the following features:

Together, these features support safe, stable, and continuous operation, even in demanding applications.