An overview of the Key Components of a Substation Transformer

August 01, 2025

At ETAC, we focus on the details, from precise engineering and the careful selection of premium materials to rigorous quality control and thorough testing at every stage. This commitment ensures that every transformer we produce is safe, durable, and reliable in the most demanding environments. It consistently meets and exceeds customers’ expectations in terms of performance, efficiency and long service life.

This article builds on Part 1 by exploring additional Substation Transformer Components commonly used in modern industrial and utility designs.

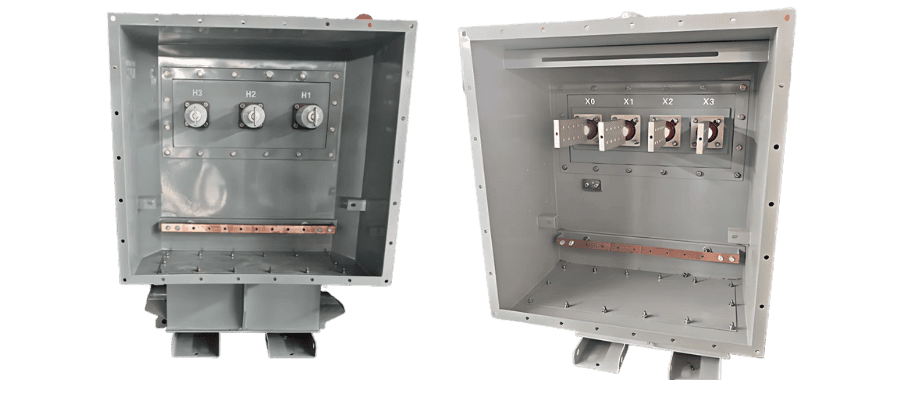

Supplied in full or half size to accommodate diverse cable entry needs, the air terminal chamber features a non-ferrous gland plate to reduce heat transfer and ensure secure, corrosion-resistant cable entry while maintaining electrical isolation. Its robust construction ensures long service life and provides convenient access for cable terminations. Integrated lifting provisions enable safe and efficient handling and installation on site. Alternatively, the design allows for a customized throat in place of the air terminal chamber, enabling direct connection with other equipment and offering flexible solutions for unique project requirements.

The transformer includes provisions for crane lifting, along with built-in features for jacking and skidding. These additional methods support flexible and safe handling during on-site installation, particularly in confined spaces where cranes or Self-Propelled Modular Transporters (SPMTs) cannot be used. These solutions enable accurate and secure positioning while minimizing risk to personnel and equipment and helping maintain installation schedules.

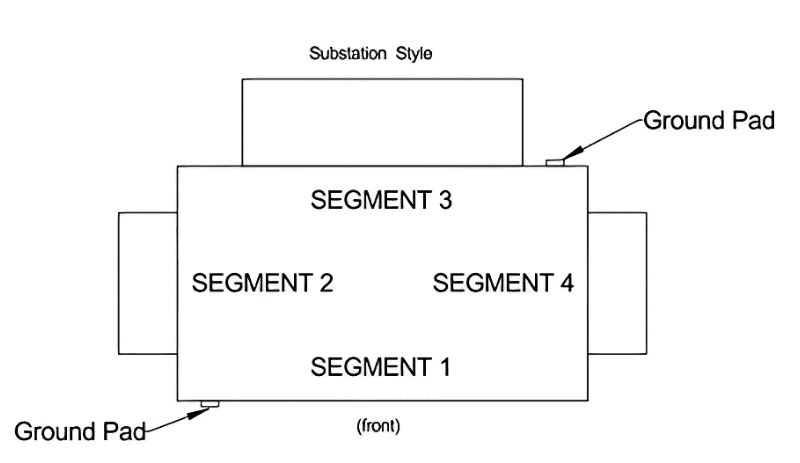

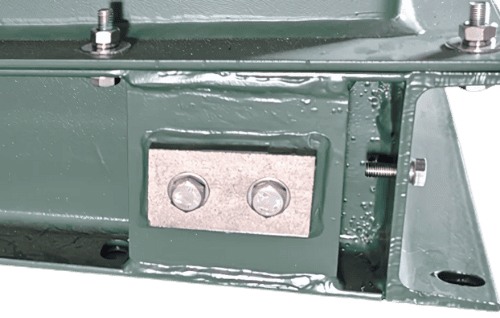

The stainless-steel ground pads are diagonally arranged to provide a low-impedance path for fault currents to safely return to the source. This configuration minimizes potential equipment damage and enhances overall safety by effectively dissipating fault currents. (Refer to the ground pad located at the lower left corner of the front view; the corresponding second pad sits diagonally opposite at the same location on the back view, forming a diagonal arrangement when viewed from the top.)

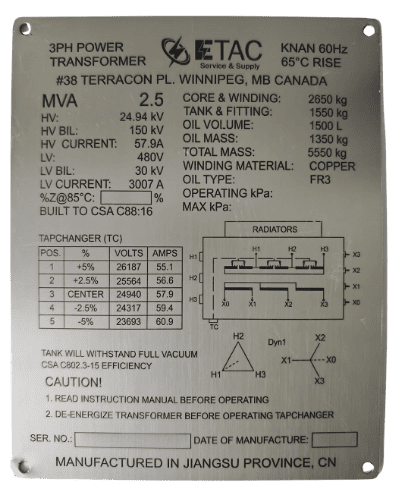

Each transformer is equipped with a high-quality stainless-steel nameplate, permanently affixed to the tank in a clearly visible location. Made from corrosion-resistant stainless steel, the nameplate ensures long-term durability and legibility, even in harsh outdoor environments. It provides complete identification and essential technical data, with information engraved or deeply stamped to remain legible throughout the transformer’s service life. Nameplate placement and content fully comply with CSA and other applicable industry standards, supporting accurate identification during installation, inspection, and maintenance. Optional custom nameplates, such as multi-language plates or additional asset tracking information, are available upon request.

Proper labels, in compliance with CSA standards, identify each component and display all required warning signs. Durable vinyl labels are standard, while stainless steel labels mounted with brackets are available upon request. A pre-installed name tag is also provided according to the customer’s specific requirements, allowing for customized identification details that ensure clear and accurate labeling for easy reference during operation and maintenance.

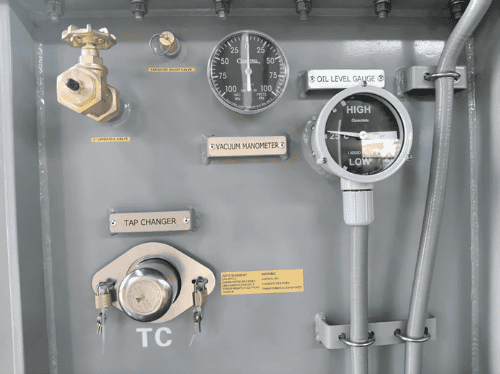

Equipped with a filter press valve to control the flow of insulating oil during filtration or pressing processes, the transformer facilitates the removal of impurities and moisture from the oil, helping maintain the transformer’s dielectric strength and prolong its operational life. The valve is designed for easy operation and secure sealing to prevent contamination during maintenance.

The drain valve provides a secure outlet for safely draining insulating oil or other dielectric fluids from the transformer tank during maintenance or oil replacement. It ensures controlled, leak-free discharge and allows easy connection to external hoses or filtration equipment, supporting safe working conditions and environmental compliance. When required, manufacturers can configure the drain valve to support Dissolved Gas Analysis (DGA) equipment, allowing convenient sampling for internal condition monitoring.

A liquid-tight conduit with properly fitted adapters protects the wiring for gauges, ensuring safe and reliable electrical connections while preventing moisture ingress and environmental damage.

At ETAC, attention to detail extends to every component integrated into our Substation Transformers. Each one is engineered for optimal performance, long-term reliability, and compliance with CSA and IEEE standards. Together, these components support operational safety, durability, and maintainability across a range of industrial and utility environments in North America.