An overview of the Key Components of a Substation Transformer

July 25, 2025

Substation transformers are normally equipped with more complex features and gauges than small sized padmount. This article in Part 1 reviews key Substation Transformer Components necessary for a safe and efficient operation.

To explore substation transformer components in action, view our substation transformer product line designed for industrial and utility needs.

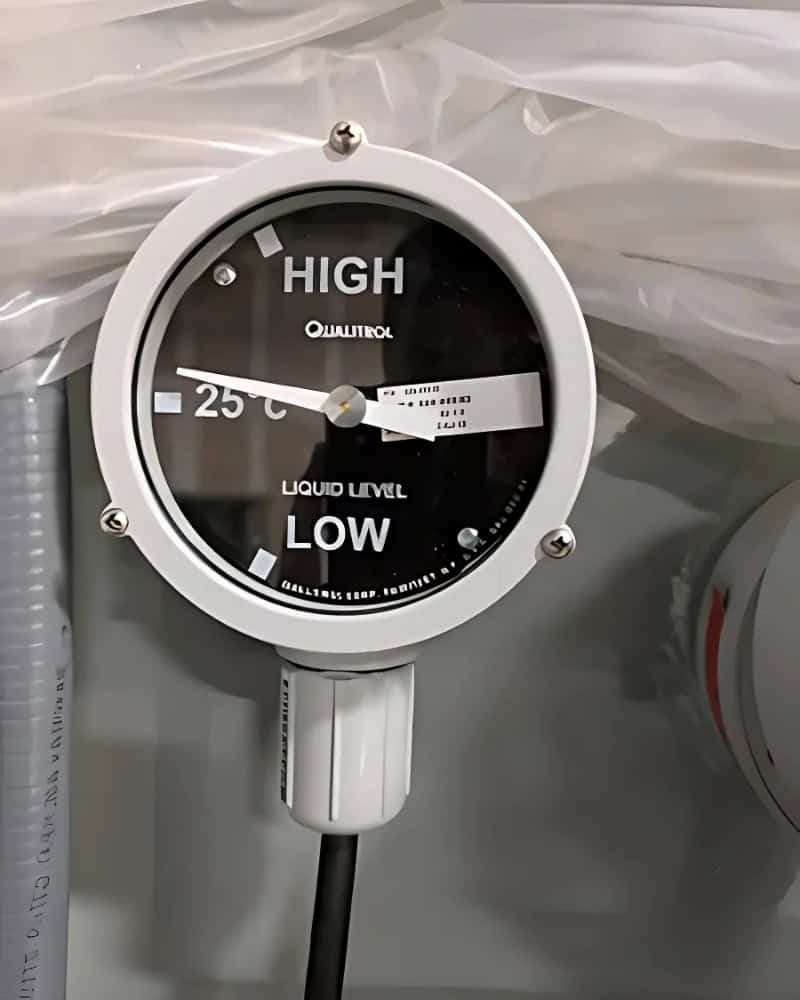

The design ensures that the insulating oil, which is crucial for cooling and insulation, is maintained at an optimal level. The indicator provides a clear, easy-to-read dial or sight gauge showing the oil level. Many liquid-level indicators have adjustable alarm contacts to warn operators of high or low oil conditions.

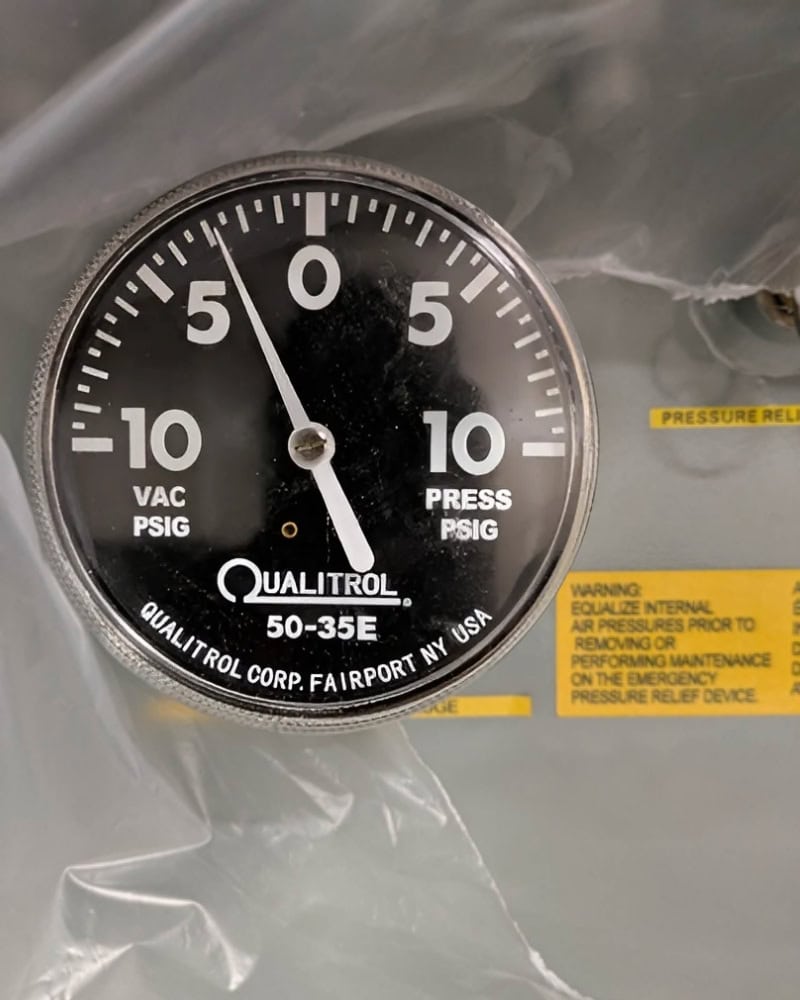

In a transformer, the internal oil and gas space expands and contracts with load changes and ambient temperature variations. In a sealed transformer, the tank must maintain safe internal pressure to prevent air and moisture from entering the insulation system. Pressure/Vacuum Gauge measures and displays the internal gas pressure inside the transformer tank relative to the external (atmospheric) pressure.

Also called an Oil Temperature Indicator (OTI), this is a critical device installed on liquid-filled substation transformers. Its main role is to measure and display the temperature of the transformer’s insulating oil, which directly affects the unit’s safe operation and lifespan. The top oil temperature is a vital parameter to indicate overloading, cooling system failures, or developing internal faults.

Excessive heat also degrades the transformer’s insulation over time, shortening its life expectancy. LTI uses built-in contacts to trigger alarms if the oil temperature exceeds safe limits, and these contacts can activate cooling fans or pumps in forced cooling systems.

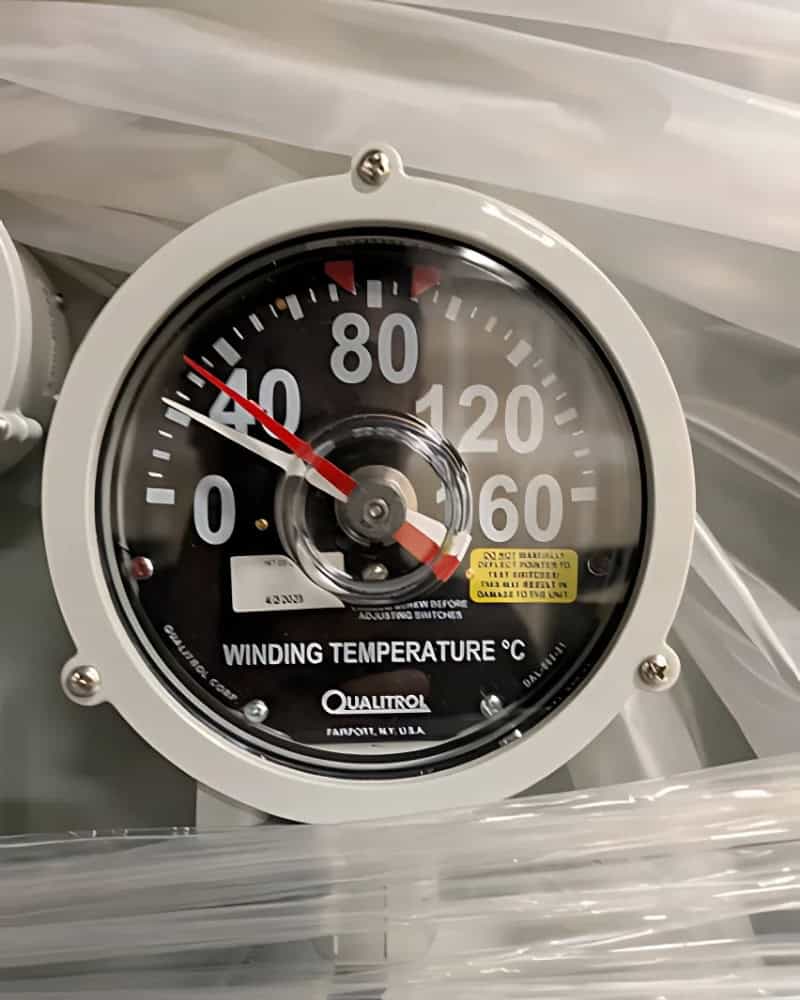

Similar to a Liquid Temperature Indicator, the Winding Temperature Indicator measures the temperature of the transformer windings. Overheating windings can lead to insulation breakdown and internal faults. It usually has adjustable contacts to trigger alarms if the winding temperature exceeds preset limits.

These contacts can also start or stop forced cooling systems, such as fans or oil pumps, to manage the temperature rise under high load. Many modern WTIs are integrated into digital transformer monitoring systems, with remote communication to SCADA or condition monitoring platforms for real-time data and trending.

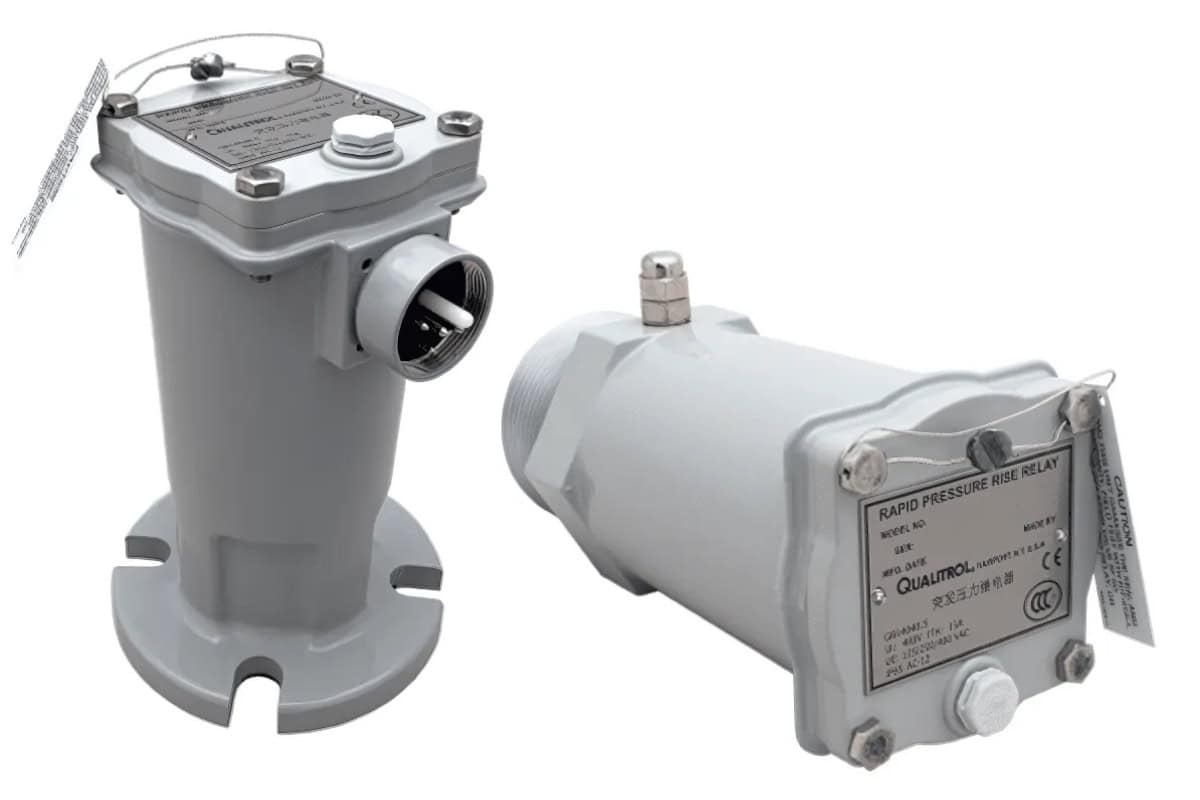

Its main function is to detect a rapid increase in internal gas pressure that could signal an incipient internal fault, such as an electrical arc, short circuit, or winding failure that generates gas bubbles or a sudden oil pressure surge inside the sealed tank, which can dramatically raise the tank’s internal pressure in seconds. The relay detects pressure changes within fractions of a second and equipped with contacts for alarm and trip functions.

The PRD is typically mounted on the main tank cover or top of the transformer. Its primary role is to protect the transformer tank from excessive internal pressure due to rapid pressure buildup from faults or abnormal conditions, by allowing this overpressure to escape in a controlled manner before the tank is damaged. A deflector cap directs vented oil safely away from the tank surface and nearby equipment, ensuring safe and reliable pressure relief operation.

The control box, also called a control cabinet or control panel, is a secure, weatherproof enclosure mounted on the transformer that houses the monitoring, control, and protection devices. It provides both local and remote access to operational data and can integrate with SCADA or smart grid systems. Critical alarms and protection circuits connect through the control box, allowing these protective circuits to trip remote alarms to prevent equipment damage and unscheduled outages. The control box also manages auxiliary cooling systems, turning fans/pump on and off by signals received from temperature gauges.

The voltage on a transmission line can vary due to load changes, line impedance, and generation variations. These fluctuations can cause the output voltage of a transformer to deviate from its rated value. Tap changers help compensate for these variations by changing the number of active turns in one of the transformer windings, usually the high-voltage winding. There are two main types of tap changers: Off-Load Tap Changer (OLTC) and On-Load Tap Changer (OLTC).

At ETAC, we design and build fully customizable substation and power transformers equipped with industry-standard gauges and smart monitoring systems. ETAC transformers are engineered to comply with CSA and IEEE standards and to operate reliably in diverse environments across North America. Whether you need basic monitoring or an advanced smart control package, ETAC’s transformers help you operate safely, extend equipment life, and protect your investment.