September 20th, 2024

Transformers play a crucial role in electrical power distribution, converting voltages to appropriate levels for different applications. However, as transformers operate, they generate heat due to the energy losses occurring primarily in the form of I²R losses (resistive losses) and core losses. Effective cooling is essential to ensure that transformers operate reliably and efficiently. In certain scenarios, adding a fan to the transformer’s cooling system becomes necessary to manage heat dissipation and maintain the transformer’s performance.

1. High Power Ratings:

2. Compact Designs with Limited Cooling Surface:

3. Environments with Elevated Temperatures:

For power transformers with capacities over 3 MVA, the need for enhanced cooling becomes even more critical. These transformers are often used in industrial and utility applications, where they must handle large amounts of power continuously. The high electrical loads generate significant heat, which if not properly managed, can lead to serious issues such as insulation breakdown, reduced transformer life, and even catastrophic failures.

1. Enhanced Cooling Requirements:

2. Load Fluctuations and Peak Demands:

3. Prolonging Transformer Lifespan:

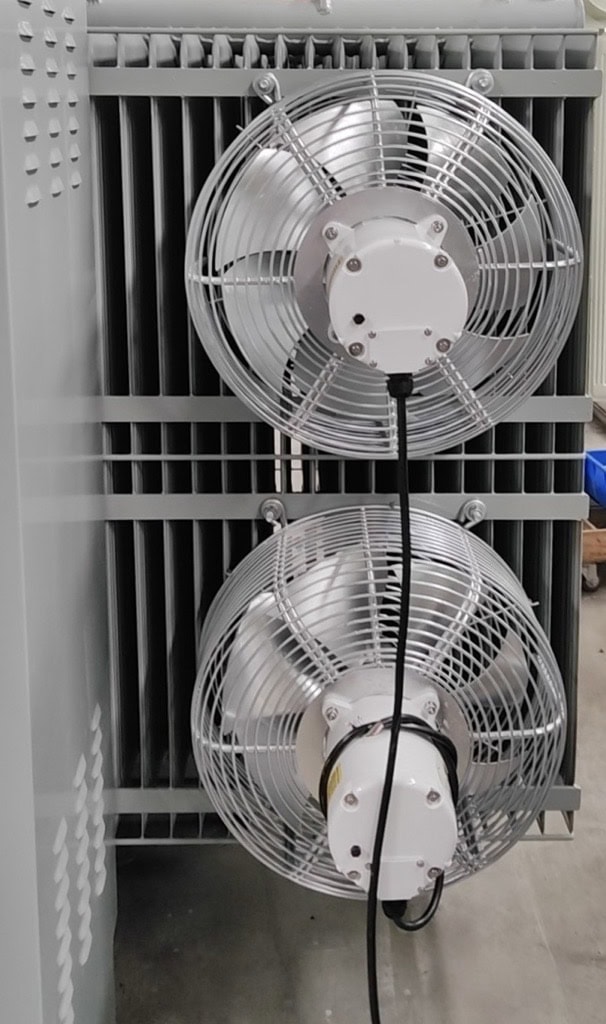

Transformers equipped with ONAN (Oil Natural Air Natural) cooling systems rely on natural convection to cool both the oil and the air surrounding the transformer. However, this cooling method can be limited when the transformer is subject to heavy loads or in high-temperature environments. By adding fans, the cooling system can be upgraded to an ONAF (Oil Natural Air Forced) system, significantly improving the transformer’s performance.

1. Capacity Boost of Up to 1/3:

2. How It Works:

3. Operational Flexibility:

The incorporation of fans in transformer cooling systems is essential for maintaining reliable performance, especially in scenarios involving high power ratings, compact designs, and elevated ambient temperatures. For power transformers with capacities over 3 MVA, fans are crucial for managing the high heat loads generated during operation. Additionally, for ONAN/ONAF transformers, the ability to increase the rated capacity by up to 1/3 with the addition of fans provides significant operational advantages, ensuring that transformers can meet increased demand while maintaining safe operating conditions. By effectively dissipating heat, fans help in prolonging the transformer’s lifespan, preventing insulation damage, and ensuring consistent performance under diverse operating conditions.