Radiator’s Impact On Transformer Radiator’s Impact On Transformer

Effective cooling of transformers is crucial for their efficiency and lifespan. This article explores the role of radiators in transformer cooling, the types of radiators, and how different radiator layouts affect transformer performance.

July 12, 2024

Transformers play a crucial role in the transmission and distribution of electrical energy. To maintain their efficiency and longevity, effective cooling systems are essential. One of the primary components responsible for cooling in transformers is the radiator. In this article, we will explore radiators’ function in transformers, the different types available, and how ETAC’s custom-designed radiators meet customer requirements while adhering to IEEE and CSA standards.

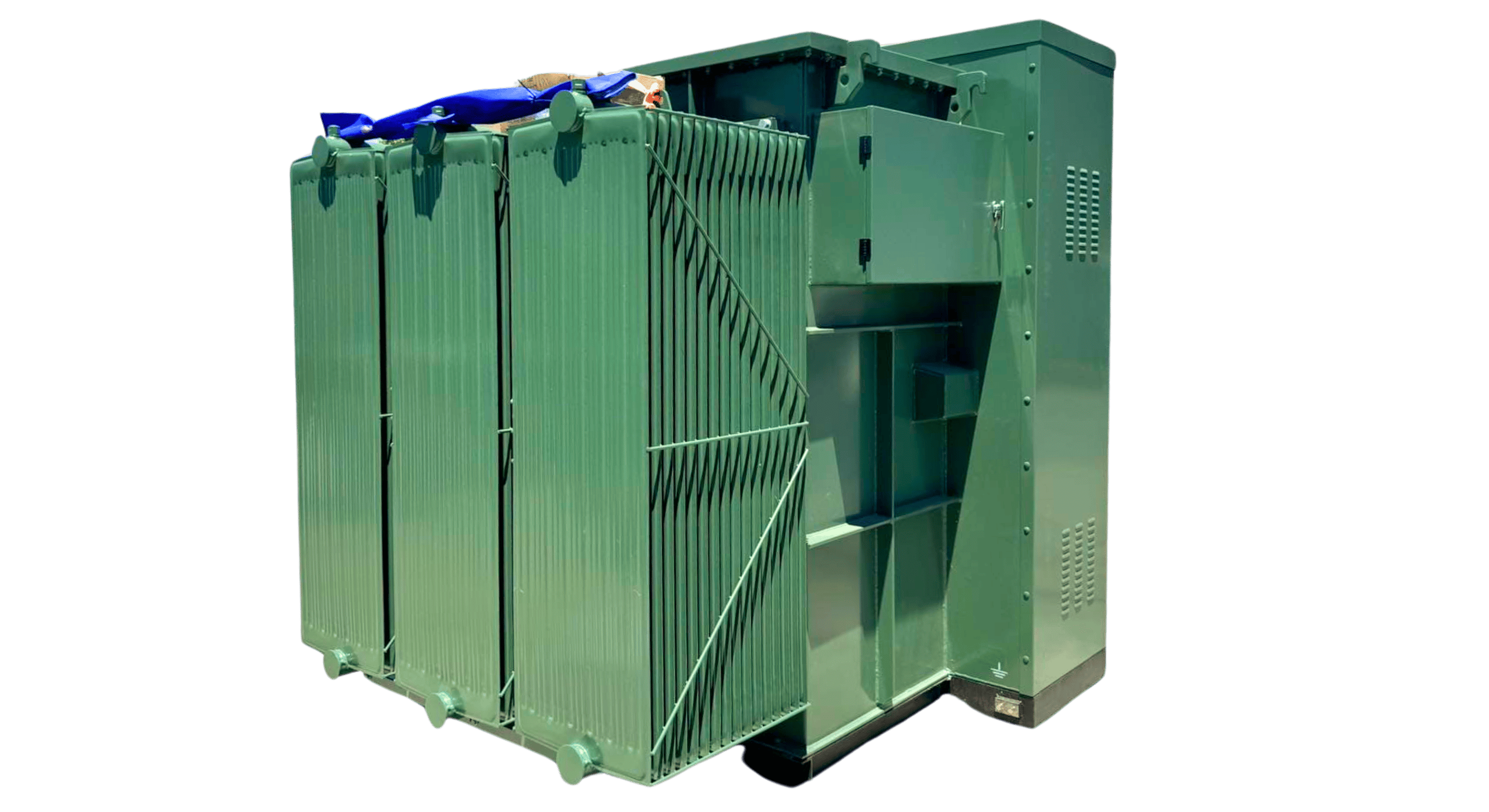

A radiator in a transformer is a critical component of its cooling system. Transformers generate heat during operation due to electrical losses in the windings and core. This heat must be dissipated to prevent overheating, which can lead to reduced efficiency, insulation degradation, and ultimately, transformer failure. Radiators help to cool the transformer by facilitating the transfer of heat from the transformer’s oil to the surrounding air.

When a transformer is operating, the current flowing through its windings produces heat. This heat raises the temperature of the transformer’s oil. This heat must be managed to maintain the transformer’s capacity and efficiency. Radiators help by increasing the surface area for heat dissipation, thereby cooling the oil more effectively. This cooling function is vital for extending the transformer’s lifespan and improving its performance.

In large power transformers, radiators are often detachable and shipped separately due to transport limitations. They are assembled on-site with the main transformer body. For smaller distribution transformers, radiators are usually integrated into the main tank. Whether detachable or integrated, the primary role of the radiator remains the same: to enhance the cooling rate of the transformer.

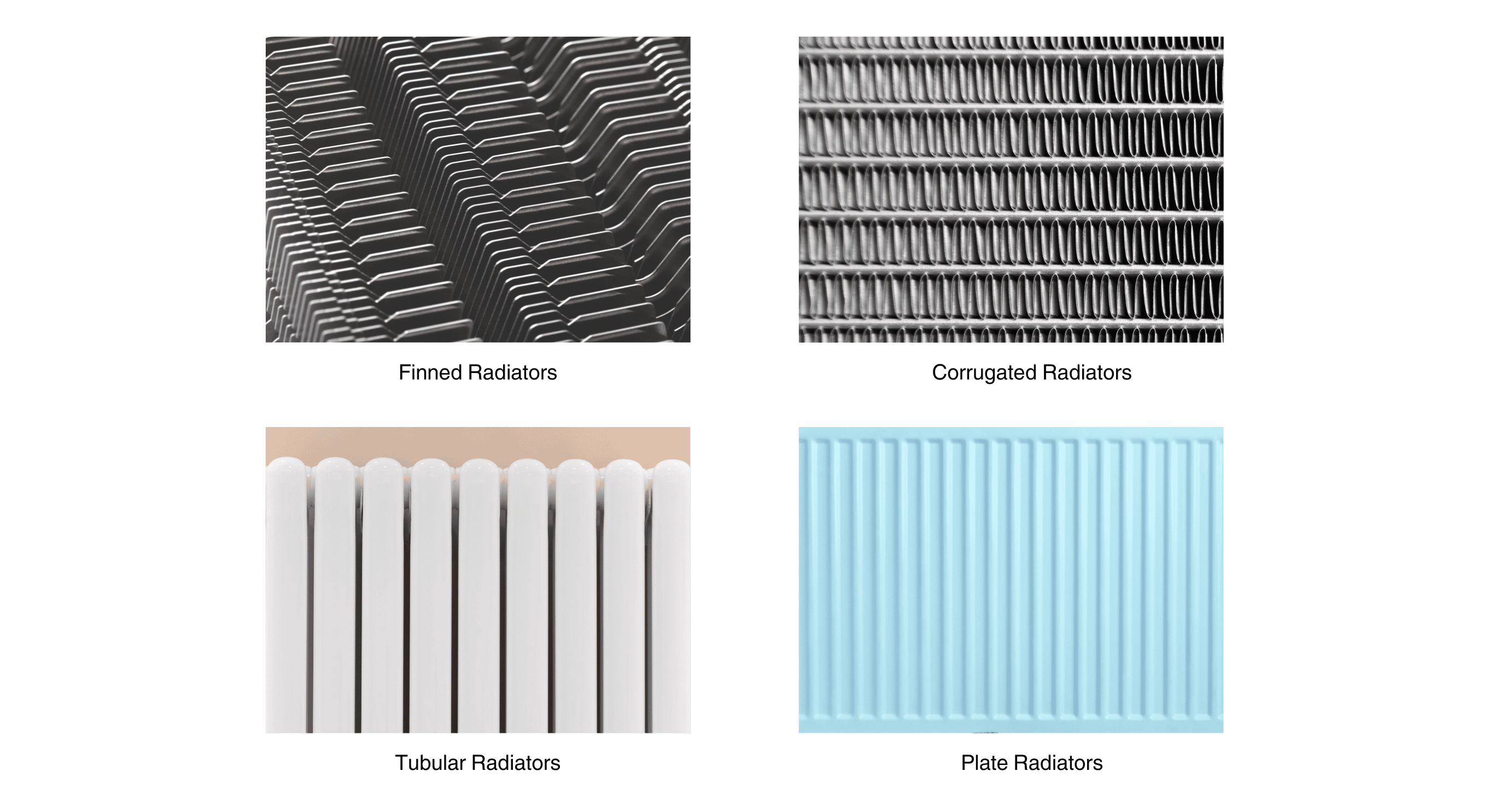

There are several types of radiators used in transformers, each designed to suit specific cooling requirements:

At ETAC Service & Supply, we understand that each transformer has unique cooling requirements. Our radiators can be custom-designed to meet these specific needs while adhering to IEEE and CSA standards. This ensures that our radiators not only provide optimal cooling but also comply with industry regulations.

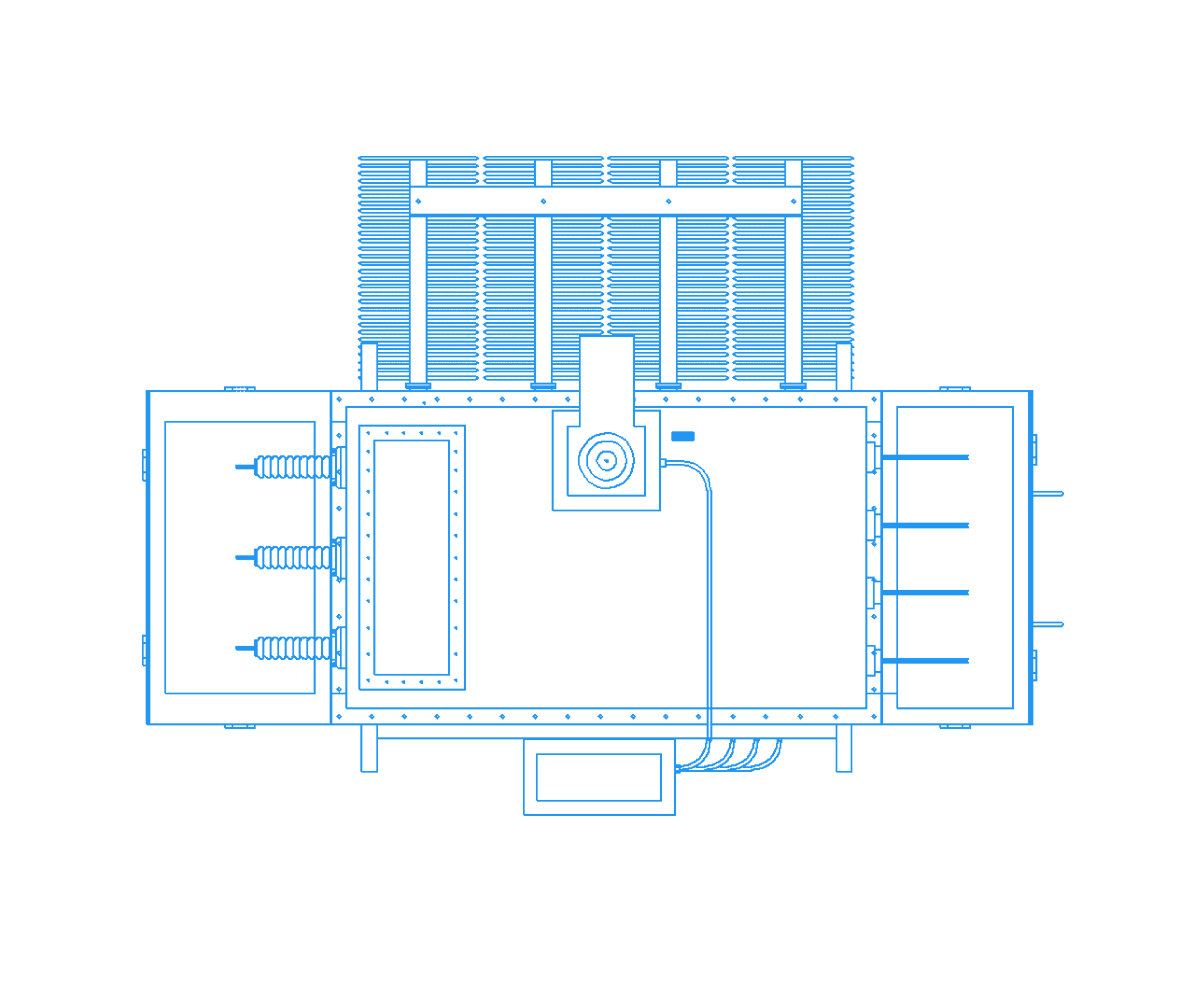

The layout of radiators in a transformer can significantly impact its cooling efficiency and overall performance. Here are some key factors:

The design of a radiator involves several principles to ensure maximum efficiency:

ETAC’s radiators are designed with the customer in mind. We offer a range of customization options, including:

In conclusion, radiators are essential for maintaining transformer efficiency and extending their lifespan. ETAC’s custom-designed radiators not only meet IEEE and CSA standards but also provide tailored solutions to meet the unique cooling requirements of each transformer. By considering factors such as surface area, air flow, and oil circulation, ETAC ensures that its radiators deliver optimal performance and reliability.