Transformers are an indispensable component of the electricity grid, managing voltage across generation, transmission, and distribution. Substation Transformers vs Distribution Transformers is a common comparison made by customers when evaluating electrical equipment, but this article explains their distinct roles within the electrical system.

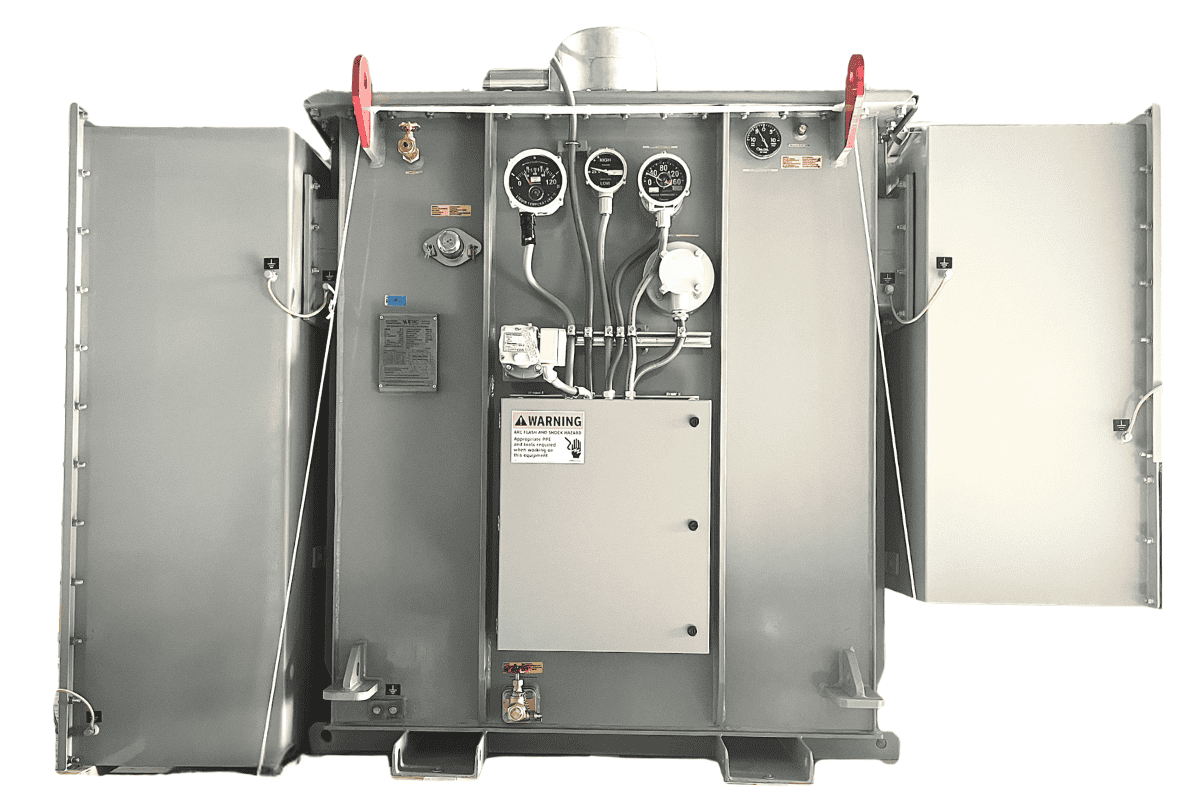

The progression of voltage transformation begins with Substation Transformers, when deployed within distribution substations. These devices are engineered to handle high voltages and high-power capacities. Their principal function is to step down bulk transmission voltage to intermediate or medium-voltage levels suitable for further downstream distribution. Installed within secured, fenced enclosures to ensure public safety and operational reliability, substation transformers often feature robust tank constructions, external monitoring equipment, and, in many cases, exposed bushings for high-voltage terminations. These transformers are considered part of critical infrastructure due to their vital role in maintaining grid stability and supporting the functioning of the power system.

For details on substation transformer design, including core construction, insulation system and winding configurations, refer to our article: Substation Transformer Design and Construction.

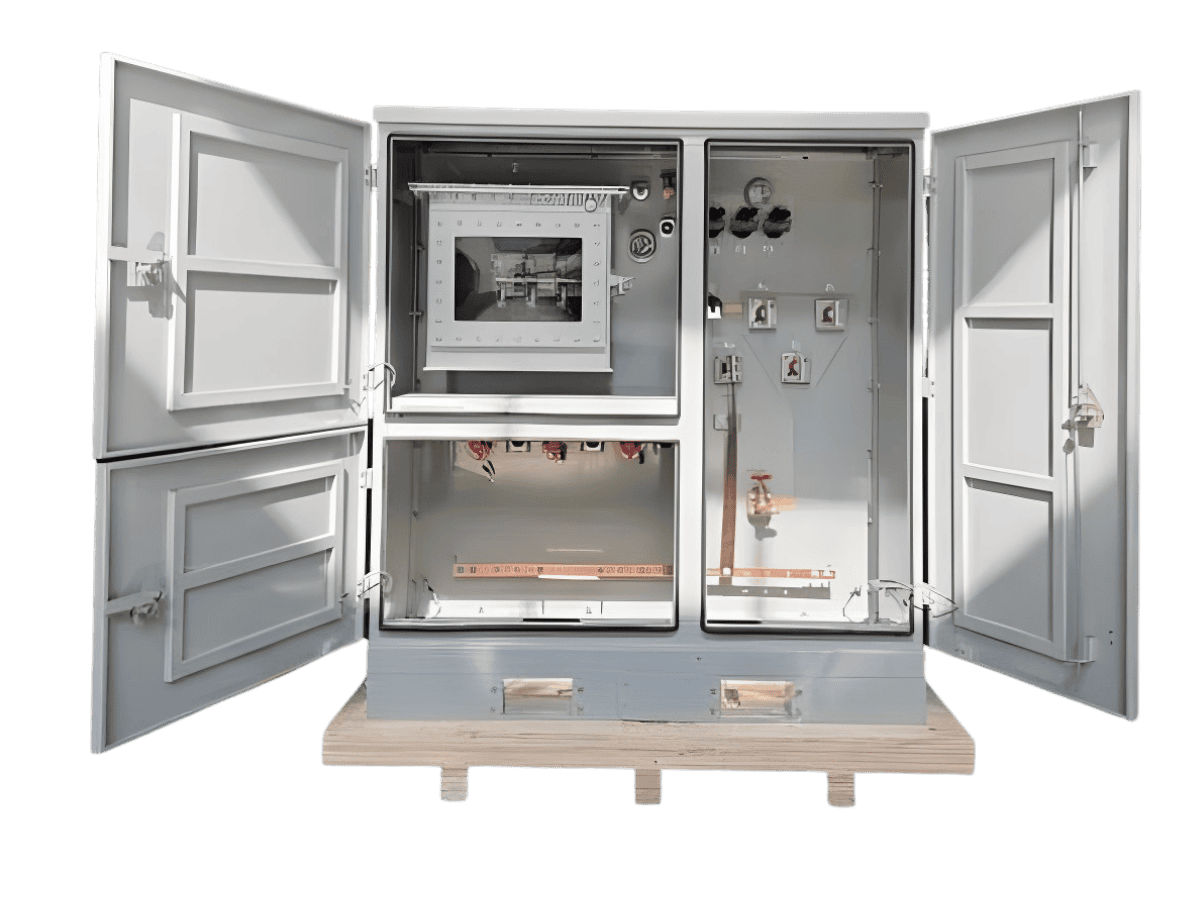

After substation transformers step down the voltage, Distribution Transformers assume the role of final-stage voltage adaptation, reducing medium voltage to the level required for direct consumption by residential, commercial and industrial use.

These transformers operate in a significantly different context: while substation transformers are part of centralized transmission infrastructure, distribution transformers are deployed extensively and ubiquitously across decentralized load centers. Their typical voltage output includes standardized three-phase configurations such as 600/347 V, 480/277 V, and 208/120 V, as well as single-phase outputs from 120V to 347V.

Distribution transformers exist in multiple physical and installation formats, depending on grid topology and infrastructure constraints:

The transition from substation transformers to distribution transformers reflects not only a change in voltage levels but also in their operational roles, design approaches, and environmental stresses.

The functional distinction between substation and distribution transformers is grounded in their respective roles within the electrical grid hierarchy, their design principles, and the stresses they must endure. Together, these transformer types ensure efficient, safe, and reliable energy transmission, minimizing losses and supporting the resilience, adaptive of the modern power system.